January 8, 2025 Graphene, Scientific alternative studies

It has been shown that graphene, graphene oxide and reduced graphene oxide can be widely used in all kinds of food packaging in the form of plastic films to extend the life of food.

Food packaging with graphene oxide. Patents and Studies

Reference study

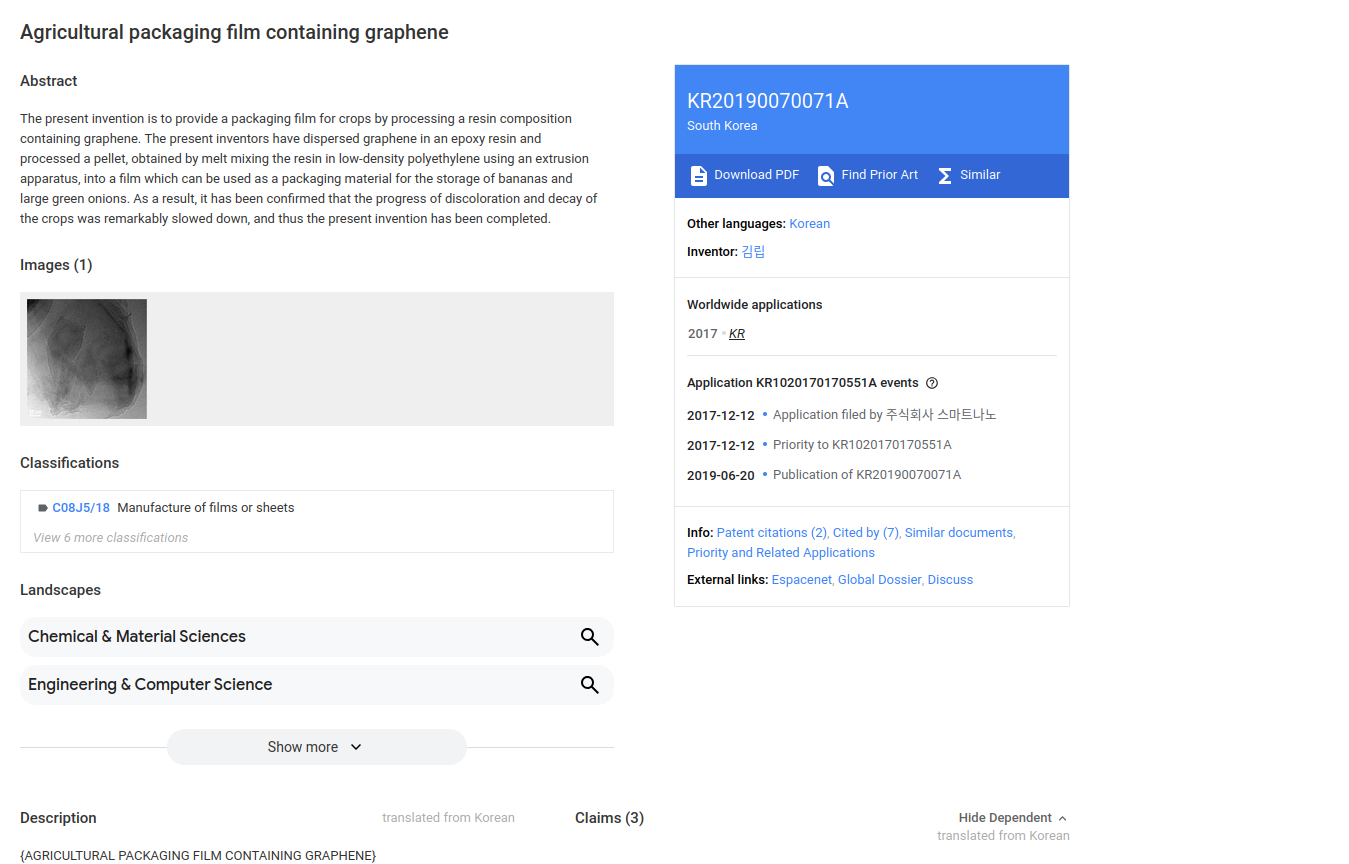

KR20190070071A., Kim, R. (2019). Agricultural packaging film containing graphene. https://patents.google.com/patent/KR20190070071A/en

Introduction

Continuing the investigation of graphene “G” and graphene oxide “GO” in fertilizers and pesticides, a patent was found which, by its nature, may provide useful information to clarify other cases of poisoning.

This is the patent (KR20190070071, 2019) that describes the method of manufacturing and using a film for food packaging.

Facts analyzed

The method is explained as follows : “The purpose of the present invention is to provide a film for food packaging by processing a resin composition containing graphene.

The authors dispersed graphene in an epoxy resin and processed a pellet obtained by mixing the resin into low-density polyethylene with an extrusion apparatus into a film that can be used as a packaging material for preserving agricultural products“.

The authors attribute to graphene the property of extending the useful life of food, but they do not mention the possible consequences for human health, since it is a toxic and harmful substance, as also repeatedly reported on this blog.

As the authors explain, “the composition of the packaging film itself is a special function and has the effect of preventing the development of discoloration and decay of crops such as vegetables and fruits during distribution and storage…there is a demand for technology that can preserve the quality of the crop for a long time“.

This is possible because the graphene film surrounding the food reduces the ingress and egress of oxygen, preventing the food from spoiling for longer.

Next, the patent provides a very interesting detail : “It is common practice to incorporate various additives into the matrix resin to express these functions.

Examples of additives include preservatives, nanomaterials, materials that emit far infrared rays, and the like“.

Specifically, the reference is to materials that emit far infrared rays, known as far infrared rays (FIR).

Although the patent does not explain the usefulness of this property, when this property is investigated, it is found that the presence of an FIR emitting agent increases antimicrobial activity, thereby improving the hygiene and shelf life of food (see Lee, JY; Kim, CH; Jung, HG; Shin, TG; Seo, JM; Lee, YR, 2008) or (Eom, SH; Park, HJ; Seo, DW; Kim, WW; Cho, DH, 2009 | Leung, TK; Huang, PJ; Chen, YC; Lee, CM, 2011).

This is confirmed in the patent with the following statement : “The present invention provides a film for packaging cultures by reducing the oxygen output through the film and forming a composite material with a resin capable of emitting far infrared rays, thereby minimizing the decrease in transparency of the substrate“.

In the tests conducted by the patent authors, the following conclusion is highlighted : “Accordingly, it was confirmed that the discoloration and deterioration of the cultures packed with the graphene-containing film were significantly delayed compared to the control film that did not contain graphene.

Banana samples packed with a control film without graphene showed significant discoloration and skin deterioration after 14 days at room temperature, but in the case of films containing graphene, the discoloration was partial“.

Although the patent was filed in 2017 and published in 2019, a related news story appeared in 2018 titled “Korean shop introduces genie banana packaging to avoid overripe fruit“, see (Barr, S. 2018).

Although the banana issue may be considered anecdotal, it is not irrelevant because there is research on “graphene oxide with chitosan” as a preservation method related to the purpose of the packaging media.

It should be clarified that “chitosan” is a polysaccharide compound used in agriculture to control pests, plant diseases, and fungal infections, among other things.

In the biomedical field, it is used for its antiseptic properties (including in combination with graphene or graphene oxide, as in the case mentioned above), disinfection and wound healing (Choudhary, P.; Ramalingam, B. and Das, SK, 2020).

It has also been used for wound healing in a study by (Mangadlao, J., Fan, J., De Leon, A., Delgado-Ospina, J., Rojas, JG and Advincula, R., 2017) and in hydrogels in a study by (Konwar, A., Kalita, S., Kotoky, J. and Chowdhury, D., 2016).

Going back to the banana test, the study by (Wang, H.; Qian, J.; Ding, F. 2018) stands out, where the researchers work on the development of biodegradable plastic packaging based on chitosan and graphene oxide, stating that “compared to pristine chitosan, chemically crosslinked chitosan/graphene oxide films have better mechanical capacity and oxygen barrier properties.

Graphene oxide stacks and expanded graphite could also be added to chitosan to form films.

Selectivity and safety have demonstrated their potential as antimicrobial films for food preservation“.

Another relevant statement of the experiment is related to the pH level of the compound and the ionization of chitosan : “Chitosan was highly ionized by the poly(acrylic acid) counterion and could attract more graphene oxide on the bulk film.

The multilayer films were shown to possess the combinatorial properties of the components, inhibiting the growth of Escherichia coli (E. coli) and exhibiting higher antioxidant activity with increasing number of bilayers“.

This statement shows the relationship between ionization and graphene oxide.

Other authors also agree on the use of graphene oxide in products and packaging processes (Venkateshaiah, A.; Cheong, JY; Habel, C.; Wacławek, S.; Lederer, T.; Cernik, M.; Agarwal, S. 2019; Li, F.; Yu, HY; Wang, YY; Zhou, Y.; Zhang, H.; Yao, JM; Tam, KC 2019).

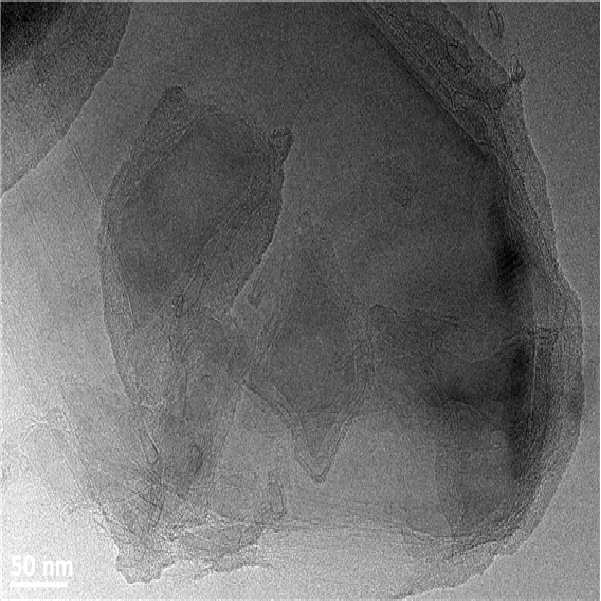

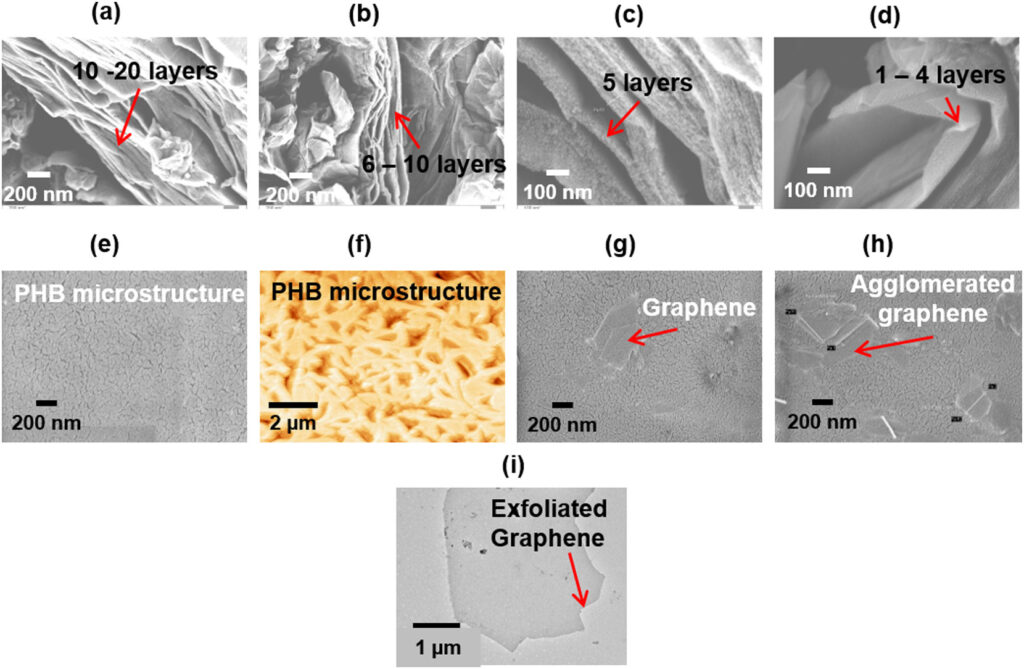

To conclude the analysis of the patent referred to in the entry (KR20190070071A. Kim, R. 2019), it is worth mentioning that the graphene used in the film has an average thickness between 1 and 20 atomic layers.

The other components are polyethylene resin, polypropylene, and polyethylene terephthalate in addition to the aforementioned graphene.

Other studies

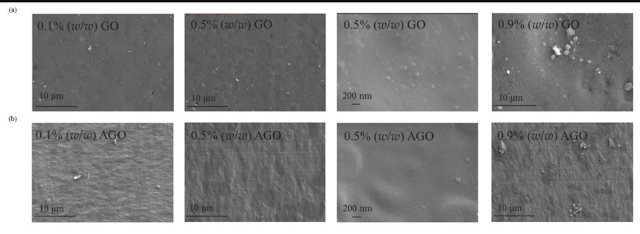

A recent example is that of (Cheng, Y.; Dong, H.; Wu, Y.; Xiao, K. 2021), who developed a vacuum packaging material containing amidated graphene oxide/polyetherether ketone sulfonate, also known by its acronym AGO/SPEEK, aimed at the preservation of cherry tomatoes.

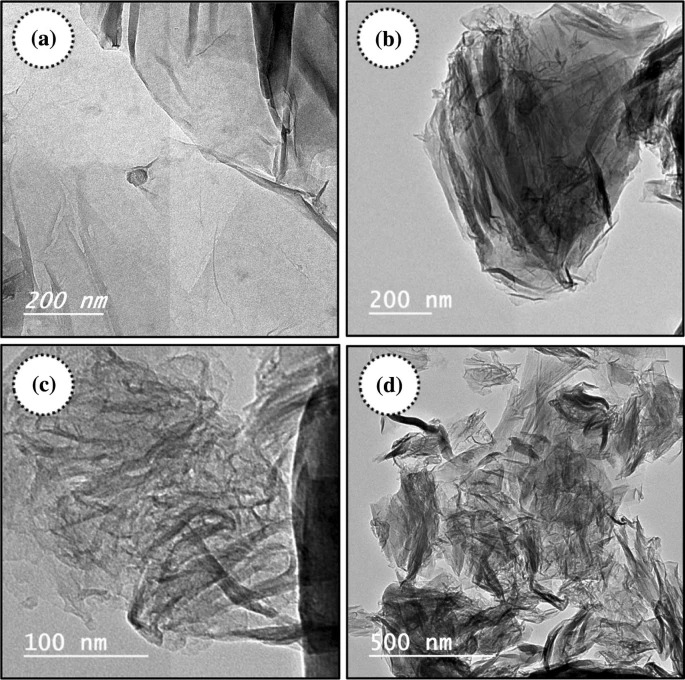

Returning to the banana packaging experiments, the study by (Chowdhury, S.; Teoh, YL; Ong, KM; Zaidi, NSR; Mah, SK 2020) which presents the development of PVA films in polyvinyl alcohol with GO graphene oxide deserves mention.

The authors state that “it has also been shown that the PVA-GA-GO film possesses cytotoxic activity against bacteria as it is able to form a 10 mm zone of inhibition against Escherichia coli, which can be considered as moderate antibacterial activity.

The bacterial cytotoxicity of the PVA-GA-GO film is attributed to the insertion of the GO nanoplate into the cell membrane.

Due to the shape of the sharp, blade-like edges of GO, it could penetrate and destroy the phospholipids of Escherichia coli (E. coli) membranes, leading to the formation of nanoscale cavities and holes“.

A very interesting study, since graphene oxide has the peculiarity of penetrating, depositing and accumulating inside the cells of bacteria.

The authors confirm this as follows : “GO has a higher density of functional groups and is small in size, which gives it the ability to contact and interact with bacterial cells, leading to cellular deposition.

Through direct contact, graphene nanosheets can stimulate stress on the cell membrane, causing its destruction and ultimately leading to cell death“.

However, if GO graphene oxide is able to cause cell death in bacteria, it could also do so in human cells.

This is shown in studies by (Mittal, S .; Kumar, V .; Dhiman, N .; Chauhan, LKS; Pasricha, R .; Pandey, AK, 2016 | Lim, MH ; Jeung, IC; Jeong, J . Yoon, SJ; Lee, SH; Park, J.; Min, JK, 2016 | Gurunathan, S.; Arsalan-Iqbal, M.; Qasim, M.; Park, CH; Yo, H.; Hwang, JH; Hong, K., 2019 | Palmieri, V.; Lauriola, MC; Ciasca, G.; Conti, C.; De-Spirito, M.; Papi, M., 2017 | Chen, L.; Hu, P.; Zhang, L.; Huang, S.; Luo, L.; Huang, C., 2012 | Seabra, AB; Paula, AJ; de Lima, R.; Alves, OL; Durán, N., 2014).

The work of (Ghanem, AF; Youssef, AM; Rehim, MHA 2020) is interesting for the introduction of graphene oxide into polystyrene packaging.

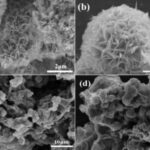

This is stated verbatim as follows : “Hydrophilic graphene oxide (GO) prepared by the Hummer method was grafted onto the surface with poly(4-vinylbenzyl chloride), p (VBC), by an in situ radical polymerization method.

Graphene oxide/poly(4-vinylbenzyl chloride), GP (VBC), was then dispersed in the polystyrene matrix to obtain nanocomposite thin films with different filler ratios (5%, 10%, 15%, 20% and 25%) by weight“.

This means that graphene oxide will be applied to any polystyrene product that comes in contact with food, such as plastic trays, heat-sealable lids, cans, plastic foams, and take-out containers.

In short, all plastic food containers.

In the study by (Goh, K.; Heising, J. K.; Yuan, Y.; Karahan, E. H.; Wei, L.; Zhai, S.; Chen, Y. 2016), poly(lactic acid) PLA was used in combination with reduced graphene oxide (rGO) to improve the packaging properties and solve the water vapor and oxygen barrier problems presented by many petroleum derivatives.

To address this problem, a PLA-graphene composite film with a sandwich architecture was designed using an impermeable reduced graphene oxide (rGO) as the central barrier and commercial PLA films as the outer protective encapsulation.

The authors conclude that “the large lateral dimension of rGO and the reduced interstitial space between the rGO sheets created an extended and tortuous diffusion path, up to 1,450 times the barrier thickness of rGO.

The interlaced architecture gave the PLA-rGO composite film good processability, which enhances its handling and adaptability.

Simulations using the PLA-rGO composite food packaging film for edible oil and potato chips also show an extension of the shelf life of these oxygen- and moisture-sensitive foods by at least eight times“.

As shown in Figure 9, the graphene oxide barrier acts as a sealant for the oxygen contained in the bag or container containing the food, thereby extending the shelf life of the food itself.

Other authors (Huang, HD; Ren, PG; Xu, JZ; Xu, L .; Zhong, GJ; Hsiao, BS; Li, ZM, 2014) also used the same approach with polylactic acid (PLA), but combined with graphene oxide “GONS” nanosheets.

Among the most notable results was a “strong decrease in the gas permeability coefficients of the PLA films, where the oxygen and carbon dioxide permeability coefficients were reduced by about 45 percent and 68 percent, respectively, with a GONS loading of less than 1.37 percent by volume“.

The PLA-GONS combination has the distinction of being able to protect food from ultraviolet light, as the researchers themselves point out : “The incorporation of GONS could effectively block the transmission of ultraviolet light in nanocomposite films and provide excellent thermal stability to the PLA matrix, demonstrating the material’s suitability for large-scale production of high-barrier films in the packaging industry“.

The development of environmentally biodegradable materials for food packaging has also been investigated (Manikandan, NA; Pakshirajan, K.; Pugazhenthi, G., 2020).

In this work, a material based on polyhydroxybutyrate (PHB) (semi-crystalline thermoplastic biopolymer) and graphene “G” is created.

As in the above studies, mechanical and barrier properties will be evaluated for food protection and durability.

Interestingly, the authors mention the cytotoxicity of graphene, stating that “the PHB/Gr-NP nanocomposite is less cytotoxic and highly biodegradable by soil biomes” and adding that it “increases the durability fourfold after simulating moisture and oxygen sensitive foods (chips and dairy products)”.

Final reflections

It has been shown that graphene “G”, graphene oxide “GO” and reduced graphene oxide “rGO” can be widely used in all kinds of food packaging in the form of plastic films to extend the life of food.

The scientific literature in this area is extensive.

For example, the following papers can be cited: (KR20190070071A. Kim, R. 2019 | Venkateshaiah, A.; Cheong, J.Y.; Habel, C.; Wacławek, S.; Lederer, T.; Cernik, M.; Agarwal, S. 2019 | Li, F.. Yu, H.Y.; Wang, Y.Y.; Zhou, Y.; Zhang, H.; Yao, J.M.; Tam, K.C. 2019 | Cheng, Y.; Dong, H.; Wu, Y. Xiao, K. 2021; Chowdhury, S., Teoh, Y. L., Ong, K. M., Zaidi, N. S. R., Mah, S. K. 2020; Ghanem, A. F., Youssef, A. M., Rehim, M. H. A. 2020; Goh, K., Heising, J. K., Yuan, Y., Karahan, E. H., Wei, L., Zhai, S., Chen, Y. 2016).

They also deserve mention (Huang, HD; Ren, PG; Xu, JZ; Xu, L.; Zhong, GJ; Hsiao, BS; Li, ZM, 2014 | Manikandan, NA; Pakshirajan, K.; Pugazhenthi, G.. 2020 | Yu, J.; Ruengkajorn, K.; Crivoi, DG; Chen, C.; Buffet, JC; O’Hare, D. 2019 | Terzioglu, P.; Altin, Y.; Kalemtas, A.; Bedeloglu, AC 2020).

All these studies can also be found by searching for “graphene oxide“, “food“, “film“, “packaging“.

Graphene could be used in combination with chitosan (or chitosan) or other components to make bandages, dressings and wound healing products (Fan, Z.; Liu, B.; Wang, J.; Zhang, S.; Lin, Q.; Gong, P.; Yang, S. 2014; Lu, B.; Li, T.; Zhao, H.; Li, X.; Gao, C.; Zhang, S.; Xie, E. 2012).

The use of graphene oxide in hydrogels for hygienic purposes has also been demonstrated (Konwar, A.; Kalita, S.; Kotoky, J.; Chowdhury, D., 2016 | Papi, M.; Palmieri, V.; Bugli, F.; De Spirito, M.; Sanguinetti, M.; Ciancico, C. Conti, C. 2016 | Wang, X.; Liu, Z.; Ye, X.; Hu, K.; Zhong, H.; Yuan, X.. Guo, Z. 2015 | Jafari, Z.; Rad, A.S.; Baharfar, R.; Asghari, S.; Esfahani, M.R. 2020 | Cheng, W.; Chen, Y.; Teng, L.; Lu, B.; Ren, L.; Wang, Y. 2018).

All products derived from these applications may contain graphene and may have an impact on human health.

Therefore, it is recommended that plastic films and food packaging be tested for graphene so that they can be removed from the market or prevented from being purchased by consumers.

Graphene in packaging can contaminate food through contact and deposition, both during degradation and during human handling of the packaging.

It is therefore essential to detect it in the laboratory.

If graphene is confirmed in such materials intended for food packaging, it would provide a new route of contamination and another explanation for the magnetic phenomenon in food.

In addition to the ionizing effect on graphene, the food itself could become magnetic after days of continuous contact.

This would also explain the magnetic properties of the packaging.

In fact, transdermal penetration, i.e. penetration of graphene oxide with and without chitosan through the skin, has been widely demonstrated (Justin, R.; Chen, B. 2014) as a method for drug and medication delivery.

See, for example, cases of administration of “ondansetron” (a drug for the treatment of nausea and vomiting) in animals (Li, H.; Jia, Y.; Liu, C. 2020).

Regarding the transdermal properties of graphene oxide, more than 100 related studies supporting this claim can be accessed using the queries “graphene oxide” and “transdermal“.

Bibliography

1.Barr, S. (2018). Korean store unveils ‘genius’ banana packaging to avoid overripe fruit. https://www.independent.co.uk/life-style/food-and-drink/banana-packaging-ripe-hack-korea-supermarket-e-mart-ssg-plastic-waste-a8485066.html

2.Chen, L.; Hu, P.; Zhang, L.; Huang, S.; Luo, L.; Huang, C. (2012). Toxicity of graphene oxide and multi-walled carbon nanotubes against human cells and zebrafish. Science China Chemistry, 55 (10), pp. 2209-2216. https://doi.org/10.1007/s11426-012-4620-z

3.Cheng, W.; Chen, Y.; Teng, L.; Lu, B.; Ren, L.; Wang, Y. (2018). Antimicrobial colloidal hydrogels assembled by graphene oxide and thermo-sensitive nanogels for cell encapsulation. Journal of colloid and interface science, 513, pp. 314-323. https://doi.org/10.1016/j.jcis.2017.11.018

4.Cheng, Y.; Dong, H.; Wu, Y.; Xiao, K. (2021). Preparation of an Amidated Graphene Oxide/Sulfonated Poly Ether Ether Ketone (AGO/SPEEK) Modified Atmosphere Packaging for the Storage of Cherry Tomatoes. Foods, 10 (3), 552. https://doi.org/10.3390/foods10030552

5.Choudhary, P.; Ramalingam, B.; Das, SK (2020). Fabrication of Chitosan-Reinforced Multifunctional Graphene Nanocomposite as Antibacterial Scaffolds for Hemorrhage Control and Wound-Healing Application. ACS Biomaterials Science & Engineering, 6 (10), pp. 5911-5929. https://doi.org/10.1021/acsbiomaterials.0c00923

6.Chowdhury, S.; Teoh, YL; Ong, KM; Zaidi, NSR; Mah, SK (2020). Poly (vinyl) alcohol crosslinked composite packaging film containing gold nanoparticles on shelf life extension of banana. Food Packaging and Shelf Life, 24, 100463. https://doi.org/10.1016/j.fpsl.2020.100463

7.Eom, SH; Parco, HJ; Seo, DW; Kim, WW; Cho, DH (2009). Stimulating Effects of Far-infrared Ray Radiation on the Release of Antioxidative Phenolics in Grape Berries. Food science and biotechnology, 18 (2), pp. 362-366. https://www.koreascience.or.kr/article/JAKO200917639069310.page

8.Konwar, A.; Kalita, S.; Kotoky, J.; Chowdhury, D. (2016). Chitosan–Iron Oxide Coated Graphene Oxide Nanocomposite Hydrogel: A Robust and Soft Antimicrobial Biofilm. ACS Applied Material Interfaces, 8 (32), pp. 20625-20634. https://doi.org/10.1021/acsami.6b07510

9.KR20190070071A. . (2019). Agricultural packaging film containing graphene. https://patents.google.com/patent/KR20190070071A/en

10.Ventola, Z.; Liu, B.; Wang, J.; Zhang, S.; Lin, Q.; Gong, P.; Yang, S. (2014). A Novel Wound Dressing Based on Ag/Graphene Polymer Hydrogel: Effectively Kill Bacteria and Accelerate Wound Healing. Advanced functional materials, 24 (25), pp. 3933-3943. https://doi.org/10.1002/adfm.201304202

11.Ghanem, AF; Youssef, AM; Rehim, MHA (2020). Hydrophobically modified graphene oxide as a barrier and antibacterial agent for polystyrene packaging. Journal of Materials Science, Journal of Materials Science, 55 (11), pp. 4685-4700. https://doi.org/10.1007/s10853-019-04333-7

12.Goh, K.; Heising, JK; Yuan, Y.; Karahan, LUI; Wei, L.; Zhai, S.; Chen, Y. (2016). Sandwich-architectured poly (lactic acid)–graphene composite food packaging films. ACS applied materials & interface, 8 (15), pp. 9994-10004. https://doi.org/10.1021/acsami.6b02498

13.Grande, CD; Mangadlao, J.; Fan, J.; De Leon, A.; Delgado ‐ Ospina, J.; Rossi, JG; Advincula, R. (2017). Chitosan Cross‐Linked Graphene Oxide Nanocomposite Films with Antimicrobial Activity for Application in Food Industry. In Macromolecular symposia 374 (1), pp. 1600114. https://doi.org/10.1002/masy.201600114

14.Gurunathan, S.; Arsalan-Iqbal, M.; Qasim, M.; Parco, CH; Yo, H.; Hwang, JH; Hong, K. (2019). Evaluation of Graphene Oxide Induced Cellular Toxicity and Transcriptome Analysis in Human Embryonic Kidney Cells. Nanomaterials, 9 (7), 969. https://doi.org/10.3390/nano9070969

15.Huang, HD; Ren, PG; Xu, JZ; Xu, L.; Zhong, GJ; Hsiao, BS; Li, ZM (2014). Improved barrier properties of poly (lactic acid) with randomly dispersed graphene oxide nanosheets. Journal of Membrane Science, 464, pp. 110-118. https://doi.org/10.1016/j.memsci.2014.04.009

16.Jafari, Z.; Rad, AS; Baharfar, R.; Asghari, S.; Esfahani, MR (2020). Synthesis and application of chitosan/tripolyphosphate/graphene oxide hydrogel as a new drug delivery system for Sumatriptan Succinate. Journal of Molecular Liquids, 315, 113835. https://doi.org/10.1016/j.molliq.2020.113835

17.Justin, R.; Chen, B. (2014). Strong and conductive chitosan–reduced graphene oxide nanocomposites for transdermal drug delivery. Journal of Materials Chemistry B, 2 (24), pp. 3759-3770. https://doi.org/10.1039/C4TB00390J

18.Lee, JY; Kim, CH; Jung, HG; Shin, TG; Seo, JM; Lee, YR (2008). Emission of far-infrared ray in packaging paper. Journal of Korea Technical Association of the Pulp and Paper IndustryJournal of Korea Technical Association of the Pulp and Paper Industry, 40 (5), pp. 47-52. https://www.koreascience.or.kr/article/JAKO200804748553280.page

19.Leung, TK; Huang, PJ; Chen, YC; Lee, CM (2011). Physical-chemical Test Platform for Room Temperature, Far-infrared Ray Emitting Ceramic Materials (cFIR). Journal of the Chinese Chemical Society, 58 (5), pp. 653-658. https://doi.org/10.1002/jccs.201190101

20.Li, F.; Yu, HY; Wang, YY; Zhou, Y.; Zhang, H.; Yao, JM; Tam, KC (2019). Natural biodegradable poly (3-hydroxybutyrate-co-3-hydroxyvalerate) nanocomposites with multifunctional cellulose nanocrystals/graphene oxide hybrids for high-performance food packaging. Journal of agricultural and food chemistry, 67 (39), pp. 10954-10967. https://doi.org/10.1021/acs.jafc.9b03110

21.Li, H.; Jia, Y.; Liu, C. (2020). Pluronic® F127 stabilized reduced graphene oxide hydrogel for transdermal delivery of ondansetron: Ex vivo and animal studies. Colloids and Surfaces B: Biointerfaces, 195, 111259. https://doi.org/10.1016/j.colsurfb.2020.111259

22.Lim, MH; Jeung, IC; Jeong, J.; Yoon, SJ; Lee, SH; Parco, J.; Min, JK (2016). Graphene oxide induces apoptotic cell death in endothelial cells by activating autophagy via calcium-dependent phosphorylation of c-Jun N-terminal kinases. Acta biomaterialia, 46, pp. 191-203. https://doi.org/10.1016/j.actbio.2016.09.018

23.Lu, B.; Li T.; Zhao, H.; Li, X.; Gao, C.; Zhang, S.; Xie, E. (2012). Graphene-based composite materials beneficial to wound healinga, 4 (9), pp. 2978-2982. https://doi.org/10.1039/C2NR11958G

24.Manikandan, NA; Pakshirajan, K.; Pugazhenthi, G. (2020). Preparation and characterization of environmentally safe and highly biodegradable microbial polyhydroxybutyrate (PHB) based graphene nanocomposites for potential food packaging applications. International journal of biological macromolecules, 154, pp. 866-877. https://doi.org/10.1016/j.ijbiomac.2020.03.084

25.Mittal, S.; Kumar, V.; Dhiman, N.; Chauhan, LKS; Pasricha, R.; Pandey, AK (2016). Physico-chemical properties based differential toxicity of graphene oxide/reduced graphene oxide in human lung cells mediated through oxidative stress. Scientific reports, 6 (1), pp. 1-16. https://doi.org/10.1038/srep39548

26.Palmieri, V.; Lauriola, MC; Ciasca, G.; Conti, C.; De-Spirito, M.; Papi, M. (2017). The graphene oxide contradictory effects against human pathogens. Nanotechnology, 28 (15), 152001. https://doi.org/10.1088/1361-6528/aa6150

27.Papi, M.; Palmieri, V.; Bugli, F.; De Spirito, M.; Sanguinetti, M.; Ciancico, C.; Conti, C. (2016). Biomimetic antimicrobial cloak by graphene-oxide agar hydrogel. Scientific reports, 6 (1), pp. 1-7. https://doi.org/10.1038/s41598-016-0010-7

28.Seabra, AB; Paula, AJ; de Lima, R.; Alves, OL; Duran, N. (2014). Nanotoxicity of Graphene and Graphene Oxide. Chemical research in toxicology 27 (2), pp. 159-168. https://doi.org/10.1021/tx400385x

29.Terzioglu, P.; Altin, Y.; Kalemtas, A.; Bedeloglu, AC (2020). Graphene oxide and zinc oxide decorated chitosan nanocomposite biofilms for packaging applications. Journal of Polymer Engineering, 40 (2), pp. 152-157. http://doi.org/10.1515/polyeng-2019-0240

30.Venkateshaiah, A.; Cheong, JY; Habel, C.; Waclawek, S.; Lederer, T.; Cernik, M.; Agarwal, S. (2019) Tree gum–graphene oxide nanocomposite films as gas barriers. ACS Applied Nano Materials, 3 (1), pp. 633-640. https://doi.org/10.1021/acsanm.9b02166

31.Wang, H.; Qian, J.; Ding, F. (2018). Emerging chitosan-based films for food packaging applications. Journal of agricultural and food chemistry, 66 (2), pp. 395-413. https://doi.org/10.1021/acs.jafc.7b04528

32.Wang, X.; Liu, Z.; Sì, X.; Hu, K.; Zhong, H.; Yuan, X.; Guo, Z. (2015). A facile one-pot method to two kinds of graphene oxide-based hydrogels with broad-spectrum antimicrobial properties. Chemical Engineering Journal, 260, pp. 331-337. https://doi.org/10.1016/j.cej.2014.08.102

33.Yu, J.; Ruengkajorn, K.; Crivoi, DG; Chen, C.; Buffet, JC; O’Hare, D. (2019). High gas barrier coating using non-toxic nanosheet dispersions for flexible food packaging film. Nature communications, 10 (1), pp. 1-8. https://doi.org/10.1038/s41467-019-10362-2