October 29, 2024 Chemtrails, Graphene, Scientific alternative studies

The production costs of high-quality bulk graphene are very low, considering that it can be synthesized from organic waste.

Organic waste turned into graphene : high quality at low price

Reference study

Luong, D.X.; Bets, K.V.; Algozeeb, W.A.; Stanford, M.G.; Kittrell, C.; Chen, W.; Tour, J.M. (2020). Gram-scale bottom-up flash graphene synthesis = Gram-scale bottom-up flash graphene synthesis. Nature, 577(7792), pp. 647-651. https://doi.org/10.1038/s41586-020-1938-0

Facts analysed

The article by Luong, DX; Bets, KV; Algozeeb, WA; Stanford, MG; Kittrell, C .; Chen, W.; Tour, JM (2020) is particularly relevant as it shows that the large-scale production of graphene is perfectly feasible without requiring a high degree of sophistication or special chemical processes.

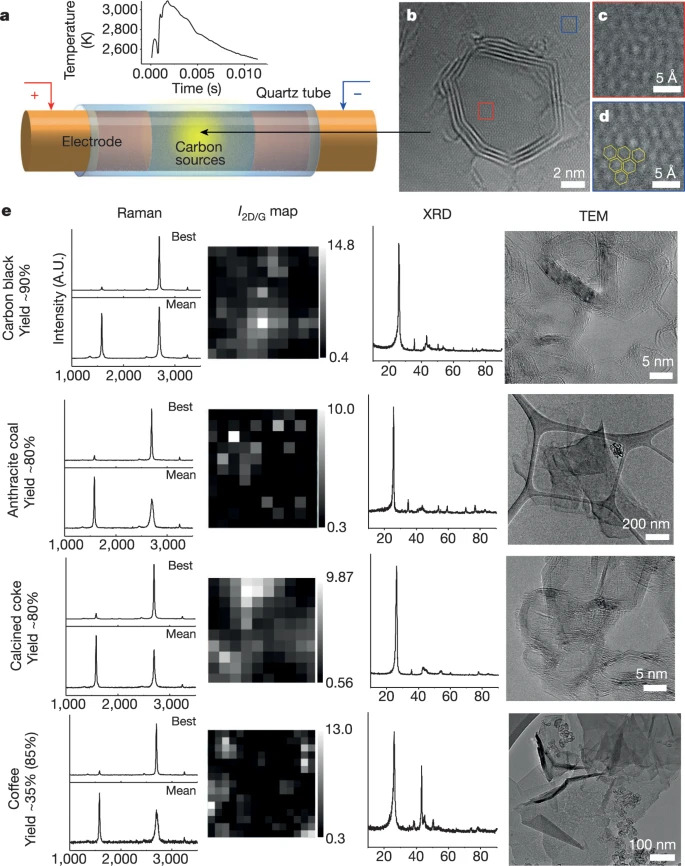

In their abstract, the researchers reveal the object of their investigation : “Here we show that instantaneous Joule heating of low-cost carbon sources, such as coal, petroleum coke, biochar, carbon black, discarded food, rubber tires and mixed plastic waste, can produce large amounts of graphene on a gram scale in less than a second”

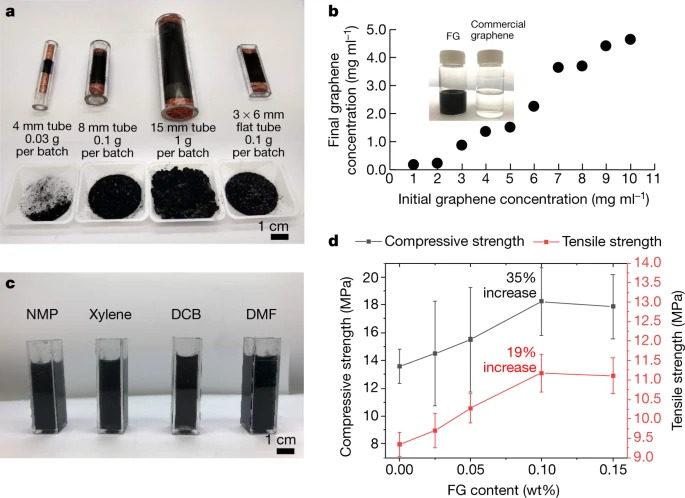

The researchers were able to produce high-quality graphene in milliseconds with little energy expenditure, using quartz electrodes and tubes, as will be explained later.

The product, called flash graphene or FG “requires no furnace, solvents or reactive gases.

Yields depend on the carbon content of the source used ; when a high-carbon source, such as soot, anthracite coal or calcined coke, is used, yields of 80 to 90 percent are obtained with a carbon purity of more than 99 percent“.

The researchers analysed the graphene samples using Raman spectroscopy and obtained “a low intensity or absent D band for Flash Graphene, indicating that Flash Graphene has one of the lowest defect concentrations reported so far for graphene“.

In the FJH process (Instantaneous Joule Heating or Flash Joule Heating), the high-carbon material to be converted into graphene is compressed (in a thin quartz tube) and enclosed in a stack of electrodes that generate a current that dramatically raises the temperature (3000 K = 2726 °C) in a temporary burst (flash) lasting a few milliseconds.

This process causes the carbon in the graphene to crystallise.

In terms of cost, the authors point out that “only 7.2 kilojoules per gram are required for the synthesis of FG, which could make it suitable for use in bulk composites of plastics, metals, plywood, cement and other building materials”

To demonstrate the validity of the method with organic waste, the case of coffee was examined, which “with its 40 percent carbon content, provides a yield based on the initial carbon content of about 85 percent“.

This is because organic waste contains mainly carbohydrates, so it is likely that any organic waste with a high carbohydrate content can be easily utilised.

However, the best yield was found with coal : “the yield of the FJH process reaches 80% to 90% from high-carbon sources such as carbon black, calcined coke or anthracite coal“.

Other materials that can be used for this purpose are : “vegetable charcoal, biochar, humic acid, keratin (human hair), lignin, sucrose, starch, pine bark, olive oil soot, cabbage, coconut, pistachio shells, potato peels, rubber tires and mixed plastics, including polyethylene terephthalate (PET or PETE), high or low density polyethylene, polyvinyl chloride, polypropylene and polyacrylonitrile“.

As for the quality of the 2D graphene, “it is optimized by adjusting the compression of the sample between electrodes (which affects the conductivity of the sample), capacitor voltage and switching duration, in order to control the temperature and flash duration.

The degassing of hydrogen, nitrogen and oxygen during the FJH process could contribute to the formation of large sheets of thin graphene, preventing overlapping layers and promoting further growth“.

Another interesting property revealed by the study was that the FG “was dispersible in a water/tensioactive solution to achieve highly concentrated dispersions reaching 4 g/l “.

This was made possible by the FJH method, which is effective in exfoliating graphene layers and is ideal for the production of aerogels, hydrogels and physiological solutions.

Applications of the discovery include the possibility of incorporating graphene into construction products such as cement or concrete.

Mixing concrete with graphene has been shown to improve its strength by 25 per cent compared to other compounds containing commercial graphene.

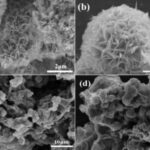

“These improvements are almost three times greater than those of other cement-graphene compounds reported with the same loading…. Microscopic images show a homogeneous distribution of FG in the cement matrix“.

These properties can be extended to other materials such as polymers, which are widely used in industry, such as polyethylene glycol.

Final thoughts

The production cost of high quality bulk graphene is very low, considering that it can be synthesised from organic waste.

This work shows that production is simple and can be easily scaled up.

The large-scale production of graphene needed to meet the demand for “vaccines”, serums, fertilisers, pesticides and atmospheric aerosol spraying and injection products (chemtrails) can thus be easily met without ever suffering from a shortage problem.

In the absence of coal and its derivatives, organic waste and plastics can be used, which are already being separated by citizens in containers for recycling.

Any industry could easily switch to graphene production, given the simplicity of the materials needed to produce it using the FJH (Flash Joule Heating) method.

On the other hand, it looks like a profitable business when you consider that 1 tonne of graphene can cost $350 to produce.

To get an idea of the profits the industry is making from graphene production, one only has to look at the sales figures for bulk graphene, which are $0.95/gram for orders over 25kg.

This means that for every tonne sold, there would be a net profit of more than $740,000, after deducting the costs of logistics, transport/distribution, purchase of raw materials for graphene production, marketing and taxes.